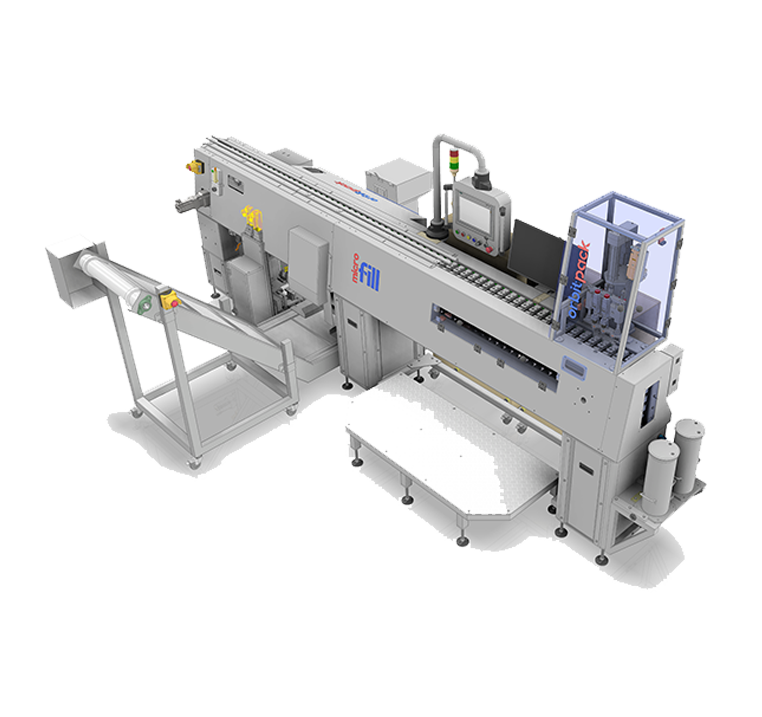

- Overview

- Capability

- Benefit

- Optional

Overview

- Orbiting with a gentle, smooth dynamic move will fill your business needs of various liquids, container sizes, and shapes

- Simple design, simple to operate, and Simple cost

Capability

- Filling Range from 60g to 55 kg

- Capability of output up to 36000 containers per hour

- filling accuracy up to 99.95% accurate

- No self-build electronic and no bespoke software

- All filling devices are compliance to OIML certification

- Up to 120 filling station

- Removable tank for of line clean

- Above 90% of components are OEM parts, No surprise bill for spare parts

Benefit

- 15-inch touch screen.

- One-page operation.

- Double flow.

- Monoblock with rinse and capper.

- Sending data weight data via OPC UA.

- Up 255 recipe file stores.

- Smart Digital product control and live level display.

- Excellent cleanability.

- Can do hot filling up to 85°c.

- Can CIP up to 140 bar pressures.

- Rejection device for filling and capping.

- Modulating valve to control the tank.

- Plug and go tooling for fast changed over.

- Main turret driven by servo motor.

- CAT 3 safety

- All turrets are electrically movable for up and down operations.

- Production report

- IO-Link sensor, getting ready for Industrial 4.0.

Optional

- ATEX environment.

- Build on Polypropylene and Polyethylene material to work on Corrosive products.

- Servo filling valve.

- Servo capper.

- Lamina flow cabin.

- IoT (Industrial 4.0).

- On screen maintenance video document.

- On-screen maintenance calendar.

- One screen line operation control for ABB robotic depalletize and palletize.

- Overview

- Capability

- Benefit

- Optional

Overview

- Tankless direct weight filler! Can handle various liquid and paste product, container size, and shape that stands.

- Simple design, simple to operate, and Simple cost.

Capability

- Filling Range from 700g to 100 kg

- Output up to 6000 containers per hour

- Filler accuracy up to 99.95%.

- No self-build electronic and no bespoke software.

- All filling devices comply with OIML certification

- Up to 2 filling stations.

- No product tank, direct feed for vector direct.

- Above 87% of components are OEM parts, No surprise bill for spare parts.

Benefit

- 10-inch touch screen.

- One-page operation.

- Double flow / double outlet.

- Sending data weight data via OPC UA.

- Up 255 recipe file stores.

- Digital product pressure display.

- Excellent cleanability.

- Can do hot filling up to 85c.

- Can CIP up to 140 bar pressures.

- Rejection system for filling.

- Plug and go tooling for fast changed over.

- Production report.

- IO-Link sensor, getting ready for IoT.

Optional

- ATEX environment.

- Build on Polypropylene and Polyethylene material to work on Corrosive products.

- Servo filling valve.

- Servo capper.

- Lamina flow cabin.

- IoT (industrial 4.0).

- On-screen maintenance video document.

- On-screen maintenance calendar.

- One screen line operation control for ABB robotic depalletize and palletize.

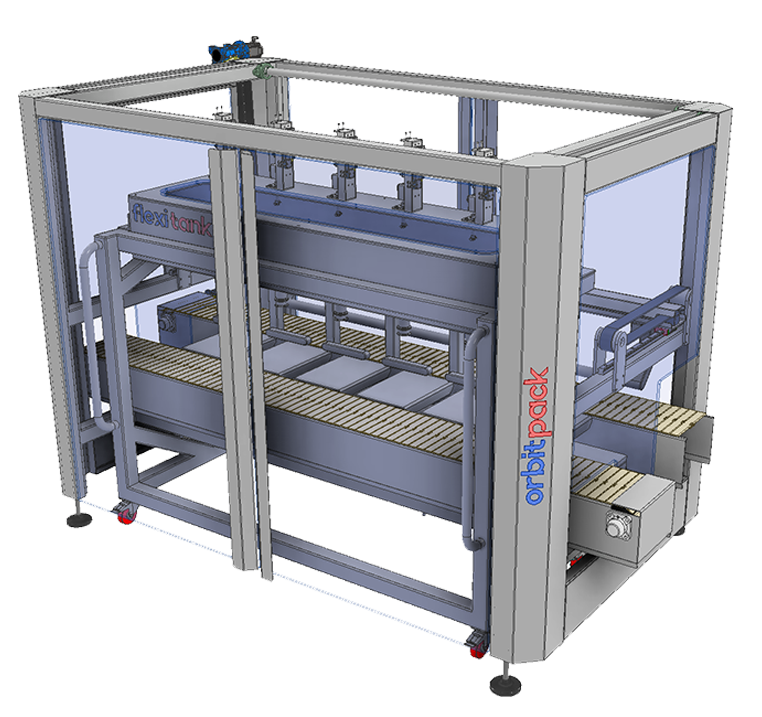

- Overview

- Capability

- Benefit

- Optional

Overview

- Smart linear filling machine. Comes with FlexiTank - a detachable tank for quick changeover.

- Simple design, simple to operate, and Simple cost.

Capability

- Filling Range from 700g to 100 kg

- Filler accuracy up to 99.95%.

- No self-build electronic and no bespoke software.

- All filling devices comply with OIML certification

- Up to 12 filling stations.

- Removable tank.

- Above 87% of components are OEM parts, No surprise bill for spare parts.

Benefit

- 10-inch touch screen.

- One page operation.

- Sending data weight data via OPC UA.

- Up 255 recipe file stores.

- Digital product pressure display.

- Excellent cleanability.

- Rejection system for filling.

- Plug and go tooling for fast changed over.

- Production report.

- IO-Link sensor, getting ready for IoT.

Optional

- ATEX environment.

- Build on Polypropylene and Polyethylene material to work on Corrosive products.

- Servo filling valve.

- Servo capper.

- Lamina flow cabin.

- IoT (industrial 4.0).

- On-screen maintenance video document.

- On-screen maintenance calendar.

- One screen line operation control for ABB robotic depalletize and palletize.

- Overview

- Capability

- Benefit

- Optional

Overview

- For all your liquid and solid products, container sizes, and shape

- Simple design, simple to operate, and Simple cost.

Footprint And Energy Consumption

- Machine size W 720 mm x L 695 mm x H 2100mm

- Machine weight 135 kg

- Voltage 24VDC at 3 amp or 230 VAC 1.2 Amp

- Pneumatic consumption 1 Nm2/h 5 bar

Capability

- Filling Range from 60g to 45 kg

- Output up to 800 containers per hour

- Filler accuracy up to 99.95%.

- No self-build electronic and no bespoke software.

- All filling devices comply with OIML certification

- Modular design can add up to 4 stations using one HMI.

- Removable tank.

- Above 90% of components are OEM parts, No surprise bill for spare parts.

Benefit

- 10-inch touch screen.

- One-page operation.

- Double flow.

- Sending data weight data via OPC UA.

- Up 255 recipe file stores.

- Digital product level display.

- Excellent cleanability.

- Can do hot filling up to 85c.

Optional

- ATEX environment.

- Build on Polypropylene and Polyethylene material to work on Corrosive products.

- Automatic capping system.

- Digital product level display.

- Filling up to 90Kg with Auto lifter.

.png)

- Overview

- Capability

- Benefit

- Optional

Overview

- Orbit VFFS (Vertical Form Fill and Seal machines) provide the speed and accuracy required to vertically fill and seal bags with a variety of products to help our customers meet their packaging needs.

- Orbitpack provides a complete vertical filling solution capable of handling any product that requires laminate film structures and polyethylene films and a variety of bag styles including gusset bags, pillow bags, doy-style stand-up bags, flat bottom bags as well as a variety of hole punches and tear notches

Capability

- Weighing Capacity: 250g to 4Kg

- Accuracy as low as ~ 0.3%

- Capability of output up 75 parts per minute

- Automatic film tracking

- High performance film pulls belts

- Bag width from 51mm to 360 mm

- Bag length from 75 mm to 400 mm on a single pull

- Up to 4 zone temperature controllers

- Filler is modular type

Benefit

- 10-inch touch screen

- One page operation

- Up 85 recipe file stores

- With servo volume can adjust the weight from HMI

- Build on SS304 body including panel

- All motor driven by variable frequency

Optional

- IO link sensing, getting ready for industrial 4.0

- On screen maintenance video document

- On screen maintenance calendar including warning data

- CIP system

- Servo volume maker

- Weight system for non-liquid product

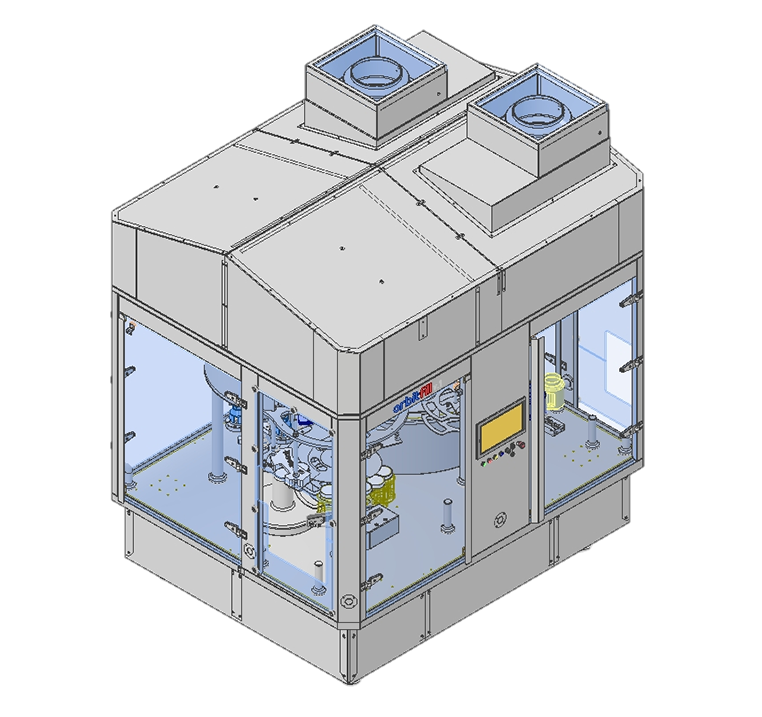

- Overview

- Capability

- Benefit

- Optional

Overview

- Medical Class Filling Machine, Accurate Filling with Vision Inspection, Auto Discharge.

Capability

- Filling Range from 5g to 170g

- Output up 2400 Dosing per hour

- Filler accuracy up to 99.6% accurate

- No self-build electronic and no bespoke software.

- Up to 380 index station stations

- Vessel up to 10 kg for product hold

- Above 87% of components are OEM parts, No surprise bill for spare parts

Benefit

- 10-inch touch screen

- One-page operation.

- Servo filling nozzle

- Servo diving

- Sending data weight data via OPC UA

- Up 255 recipe file stores

- Digital product pressure display

- Excellent cleanability.

- Plug and go tooling for fast change over

- Production report

- IO-Link sensor, getting ready for IoT

Optional

- IoT (industrial 4.0)

- On-screen maintenance video document

- On-screen maintenance calendar.

- Curing oven build in with IR heaters

- Robotic tube insertion.

- Servo funnel assembly device